2025 Industry Trends: Innovative Solutions for Best Thread Rolling Dies Global Buyers

As we approach 2025, the landscape of manufacturing and machining continues to evolve, with thread rolling dies emerging as an essential component in the production of high-strength fasteners and precision parts. According to a recent market analysis by Research and Markets, the global thread rolling dies market is expected to witness a substantial growth rate of 5.5% annually, driven by increasing demand from sectors such as automotive, aerospace, and construction. Innovative solutions in thread rolling die design and materials are paving the way for enhanced efficiency and reduced operational costs, providing significant advantages for global buyers seeking to optimize their production processes. As industries prioritize durability and performance, understanding the benefits of advanced thread rolling dies becomes crucial in maintaining competitive edge and meeting the evolving standards of quality and sustainability in manufacturing.

The Rise of Thread Rolling Dies: Key Innovations Transforming the Industry Landscape

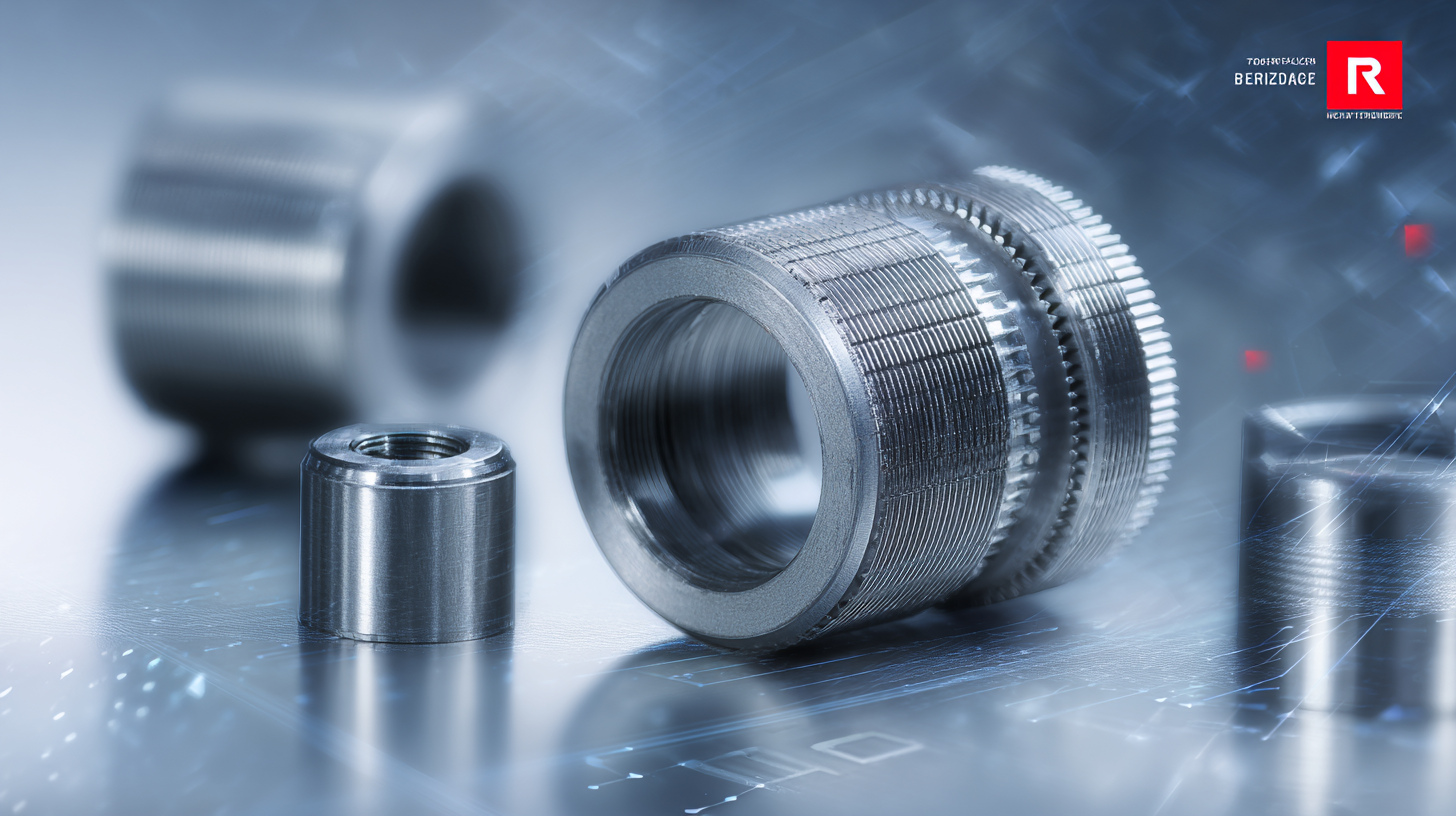

The landscape of thread rolling dies is witnessing significant transformation driven by innovative solutions tailored to meet the demands of global buyers. Key advancements in materials and manufacturing processes are paving the way for enhanced durability, reliability, and efficiency. For instance, the adoption of advanced coatings and hardened materials has substantially increased the lifespan of thread rolling dies, reducing the frequency of replacements and operational downtime.

Tip: When selecting thread rolling dies, consider opting for options with enhanced surface treatments; they not only contribute to longevity but also improve the overall performance in challenging applications.

Moreover, automation is taking center stage in the industry, with smart technology enabling more precise and consistent production. Automation streamlines the manufacturing process, ensuring that thread rolling dies are produced with minimal variation, which can significantly improve product quality.

Tip: Explore suppliers that offer automated solutions as part of their die manufacturing process. This can lead to better consistency and enhanced production efficiency, ultimately benefiting your bottom line.

Global Demand for High-Quality Thread Rolling Dies: Analyzing Market Trends and Opportunities

The global demand for high-quality thread rolling dies is poised for significant growth as industries increasingly recognize their importance in manufacturing processes. Thread rolling dies are essential for producing precise, durable threads in various materials, including metals and plastics. As sectors such as automotive, aerospace, and construction continue to expand, the need for innovative solutions that enhance the quality and efficiency of products has never been more critical. This trend prompts manufacturers to invest in advanced technologies and materials that improve the lifespan and performance of thread rolling dies.

In addition to technological advancements, the market is seeing a shift towards customization and sustainability. Buyers are now looking for dies that are tailored to specific applications, reflecting the industry's move towards more efficient and focused manufacturing. Furthermore, aligning with global sustainability initiatives, many manufacturers are adopting eco-friendly practices in the production of thread rolling dies. This transition not only meets regulatory requirements but also appeals to an increasingly conscientious consumer base.

As such, companies that can deliver high-quality, sustainable, and customizable thread rolling dies are well-positioned to seize opportunities in a rapidly evolving market.

China's Prominence in Thread Rolling Die Manufacturing: A Statistical Overview

China has established itself as a powerhouse in the manufacturing of thread rolling dies, providing innovative solutions that cater to a growing global demand. With advancements in technology and production processes, China's thread rolling die manufacturers have significantly enhanced their capabilities, leading to increased efficiency and precision in the industrial sector. Statistical data highlights that over the past decade, China has seen a remarkable surge in production output, positioning itself as the leading supplier for international markets.

Moreover, the competitive landscape has shifted as Chinese manufacturers leverage their expertise and low-cost production methods to dominate the global scene. Key players in the industry are investing heavily in research and development, focusing on creating high-performance dies that cater to various applications, from automotive to aerospace. This commitment to innovation not only strengthens China’s market position but also helps global buyers access cutting-edge technologies that can elevate their operational efficiency and product quality.

2025 Industry Trends: Innovative Solutions for Best Thread Rolling Dies Global Buyers

| Country | Market Share (%) | Annual Production (Units) | Export Value (Million USD) | Growth Rate (%) |

|---|---|---|---|---|

| China | 40 | 1,500,000 | 250 | 8 |

| Germany | 25 | 800,000 | 120 | 5 |

| USA | 15 | 600,000 | 90 | 3 |

| Japan | 10 | 500,000 | 70 | 4 |

| South Korea | 8 | 400,000 | 50 | 2 |

Sustainability in Thread Rolling Die Production: Balancing Quality and Environmental Impact

Sustainability has become a crucial consideration in the production of thread rolling dies, particularly as industries seek to balance quality with environmental impact. According to a report by Smithers Pira, the global market for sustainable manufacturing is projected to reach $3.6 trillion by 2025, reflecting a significant shift towards eco-friendly practices across various sectors. In the realm of thread rolling die production, manufacturers are beginning to adopt sustainable materials and processes that minimize waste and energy consumption. For instance, the use of recycled alloys can not only reduce environmental footprints but also maintain the durability and performance of the dies.

In addition to material innovation, companies are implementing energy-efficient technologies in their manufacturing facilities. A study by the International Energy Agency reported that adopting advanced manufacturing technologies could reduce energy consumption by up to 20% in heavy industry sectors. By investing in such technologies, thread rolling die manufacturers can improve their operational efficiency while contributing to broader sustainability goals. This commitment to environmentally responsible practices resonates well with global buyers, who are increasingly prioritizing sustainability in their sourcing decisions, as highlighted by a recent survey indicating that over 80% of consumers prefer brands that are environmentally conscious.

Future Technologies Shaping Thread Rolling Processes: Role of Automation and Precision Engineering

The thread rolling process is experiencing a significant transformation driven by advancements in automation and precision engineering. As industries progressively lean towards smart manufacturing, the integration of automated systems is enhancing production efficiency and consistency. Automation not only reduces the risks of human error but also allows for precise control over the threading process. By employing robotics and real-time monitoring, manufacturers can optimize their workflows, resulting in increased throughput and reduced cycle times.

Moreover, precision engineering is setting new standards in the quality of thread rolling dies. Techniques such as computer numerical control (CNC) machining and advanced material science are enabling the production of dies with unparalleled accuracy and durability. This level of precision is essential for meeting the stringent requirements of various applications, from aerospace to automotive. As global buyers seek innovative solutions, the synergy between automation and precision engineering will play a crucial role in shaping the future of the thread rolling industry, ensuring that products are not only manufactured efficiently but also adhere to the highest quality standards.