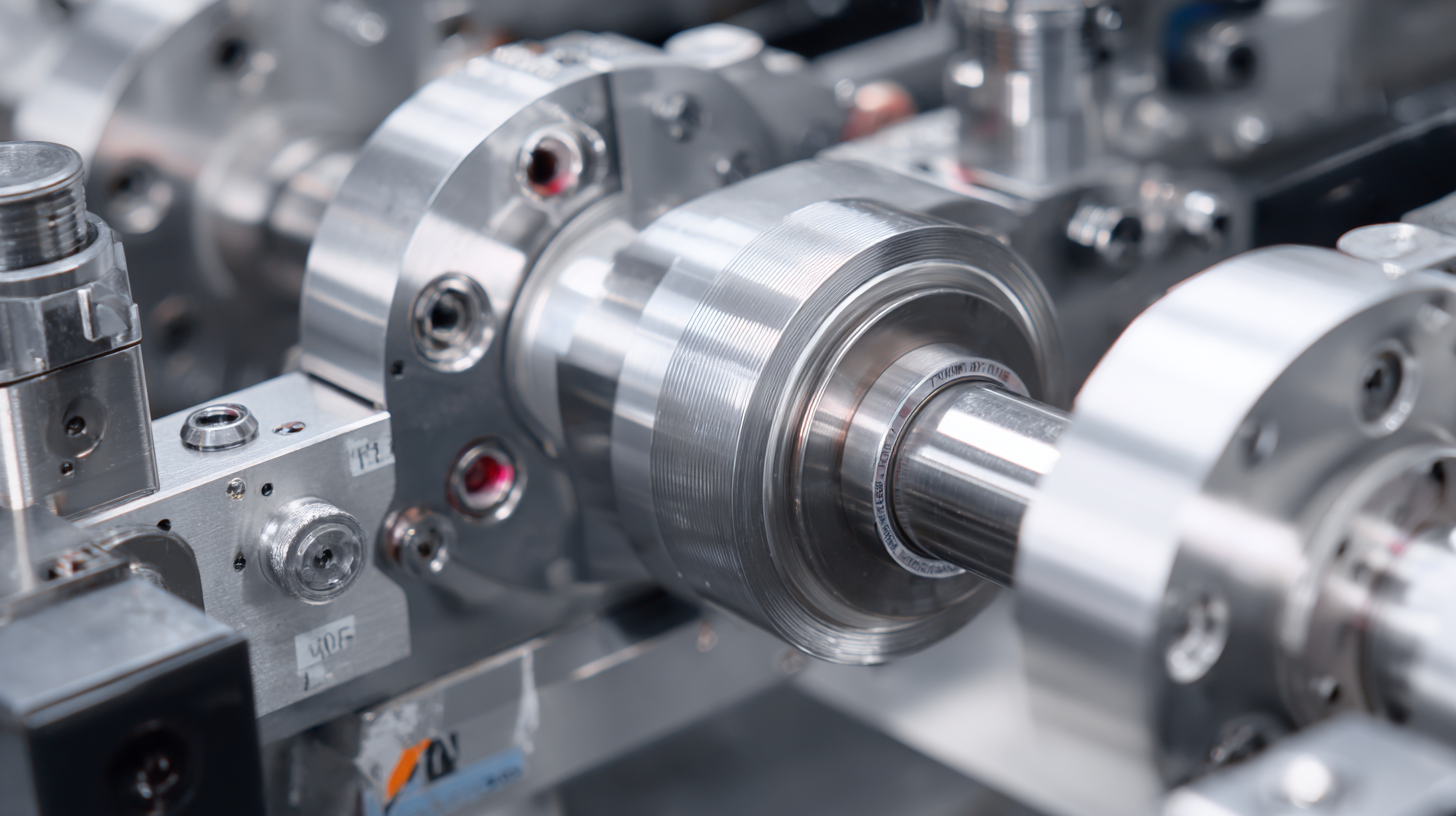

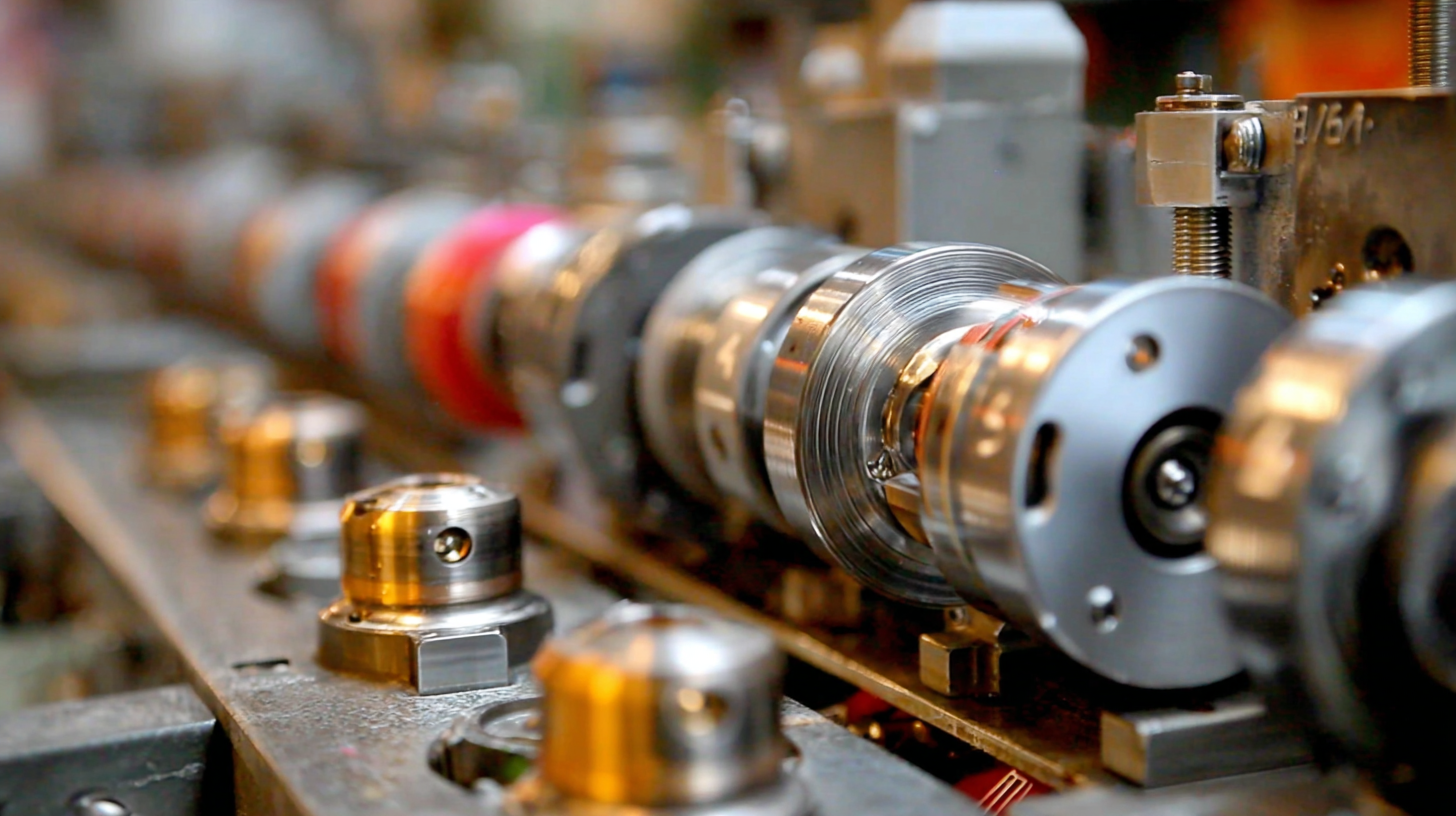

Navigating Export Certification for Best Thread Rolling Machine Components in the Global Market

In today's increasingly interconnected global market, the demand for high-quality machinery components, particularly Thread Rolling Machine Components, has surged. According to a report by Research and Markets, the global thread rolling machine market is expected to reach $4.5 billion by 2027, growing at a CAGR of 5.3%. As more manufacturers look towards China for affordable yet high-quality production, navigating the complexities of export certification becomes paramount. "实力工厂,中国制造,出口全球" aptly captures this trend, highlighting China's robust manufacturing capabilities and expanding presence in international trade. To successfully penetrate diverse markets, it is essential for exporters to understand the regulatory requirements and certifications that ensure their Thread Rolling Machine Components meet both domestic and international standards. This blog will delve into the intricacies of export certification and the strategies that can facilitate smoother entry into global markets.

Understanding Export Certification Requirements for Thread Rolling Machines

Export certification is a crucial step for manufacturers of thread rolling machines seeking to enter the global market. Understanding the specific requirements for each target country is essential to avoid potential pitfalls. Different regions may have varying standards not only for the machines themselves but also for the materials and components used. Familiarizing yourself with these regulations can streamline the export process and enhance your product's acceptance in international markets.

Tip: Before embarking on the export journey, consult with local regulatory bodies and industry associations. They can provide valuable insights into the certification process and help you navigate any legal complexities. Additionally, consider investing in legal advice to ensure compliance with international trade laws relevant to thread rolling machines.

Another critical aspect of export certification is documentation. Properly preparing and organizing necessary documents can significantly reduce delays. Certificates of conformity, technical specifications, and compliance with international standards such as ISO are often required during the export process.

Tip: Create a checklist of all required documents for each market you plan to enter. Regularly update this list as regulations change, and ensure that all stakeholders involved in the export process are aware of and understand these requirements to maintain efficiency.

Top 5 Key Certifications for Thread Rolling Machine Components

When it comes to ensuring the quality and reliability of thread rolling machine components in the global market, obtaining the right certifications is crucial. Among the fragmented landscape of certifications, five stand out as essential for manufacturers and exporters looking to enhance their credibility and market reach. These certifications not only affirm the quality of the products but also cater to the increasingly stringent standards set by international markets.

A report from the International Organization for Standardization indicates that approximately 75% of manufacturers believe that certifications improve their access to new markets and enhance customer trust. The ISO 9001 certification, for instance, is often regarded as a baseline, underscoring a commitment to quality management systems. In addition, industry-specific certifications such as the CE mark and UL certification play a pivotal role in ensuring compliance with safety and regulatory standards crucial for thread rolling machine components. As the global industry increasingly leans towards smart and interconnected solutions, aligning product certifications with evolving standards, such as those related to Matter, will further set apart leading manufacturers. These certifications ultimately drive not only compliance but also innovation in the marketplace.

Navigating Regulatory Hurdles in the Global Market for Manufacturing Parts

Manufacturers of thread rolling machine components face a myriad of regulatory hurdles when seeking to enter the global market. Each country has its own set of requirements, often leading to confusion and misalignment. From compliance with safety standards to quality certifications, navigating these regulations can be daunting for exporters. Understanding the legal frameworks—such as the ISO standards, CE marking in Europe, or FDA regulations in the United States—is critical for ensuring that products meet the necessary criteria before they can be exported.

Moreover, staying updated on changing regulations is essential, as non-compliance can result in delays, fines, or even the rejection of products at the border. Collaboration with local experts, legal advisors, or regulatory consultants can greatly reduce these risks. With a proactive approach to understanding and adapting to these hurdles, manufacturers can not only streamline their export processes but also enhance their credibility and competitiveness in the global market. By prioritizing regulatory compliance, businesses position themselves for long-term success and build trust with international partners and customers.

Best Practices for Ensuring Compliance and Faster Certification Process

Navigating the export certification landscape for high-quality thread rolling machine components can be particularly challenging in today’s competitive global market. Best practices necessitate a keen focus on ensuring compliance with international standards and regulations. According to recent industry reports, nearly 30% of certification delays are attributed to incomplete documentation and misunderstandings regarding local compliance requirements. By adopting a robust compliance management system, manufacturers can streamline their certification processes, ensuring that they meet all necessary guidelines effectively.

Moreover, leveraging automated tools for document management can enhance both efficiency and accuracy. Cloud operational capabilities are crucial in this regard, allowing companies to manage the entire lifecycle of their cloud services—from development to delivery and beyond. This approach not only supports faster certification but also aligns with the overarching goal of delivering business value through optimized service processes. Data governance practices have also been highlighted in various studies, underscoring their importance in maintaining compliance and mitigating risks associated with export certification. Utilizing best practices in both compliance and operational efficiency is essential to gaining a competitive edge in the global market.

Navigating Export Certification for Best Thread Rolling Machine Components in the Global Market

| Component Type | Certification Required | Average Processing Time | Cost Implications | Compliance Challenges |

|---|---|---|---|---|

| Gear Mechanisms | ISO 9001 | 4 Weeks | $3000 | Documentation Accuracy |

| Rolling Dies | CE Marking | 6 Weeks | $4500 | Supplier Compliance |

| Threading Machines | UL Certification | 8 Weeks | $5000 | Safety Standards |

| Lubrication Systems | FDA Approval | 5 Weeks | $2500 | Chemical Regulations |

| Control Units | RoHS Compliance | 3 Weeks | $2000 | Material Restrictions |

Top Trends Impacting Export Certification in the Thread Rolling Industry

The export certification landscape for thread rolling machine components is undergoing significant transformation, reflecting both technological advancements and evolving regulatory frameworks. One of the key trends impacting certification is the increased emphasis on sustainability. Manufacturers are now required to demonstrate compliance with environmental standards, which not only assures clients of their commitment to eco-friendly practices but also helps in gaining entry to markets that prioritize sustainability. Companies that adapt to these regulations can enhance their reputations while fostering customer trust in their products.

Another critical trend is the growing role of digitalization in export certification processes. With the rise of data analytics and blockchain technology, companies can streamline their certification workflows, enhance traceability, and ensure compliance with international standards more efficiently. This digital shift not only reduces the time and costs associated with certification but also enables manufacturers to respond quickly to changing market demands and regulatory requirements. As businesses increasingly recognize the advantages of these technological solutions, the industry as a whole is likely to see improved competitiveness in the global market.