Embracing the Future of Manufacturing Exploring the 2025 Trends for Best Thread Rolling Machines in a Global Market

The manufacturing industry is set to undergo a significant transformation by 2025, influenced by emerging technologies and shifting market demands. As noted in a recent report by Market Research Future, the global thread rolling machine market is projected to grow at a CAGR of 4.2%, driven by the increasing need for precision engineering and efficient production processes across various sectors.

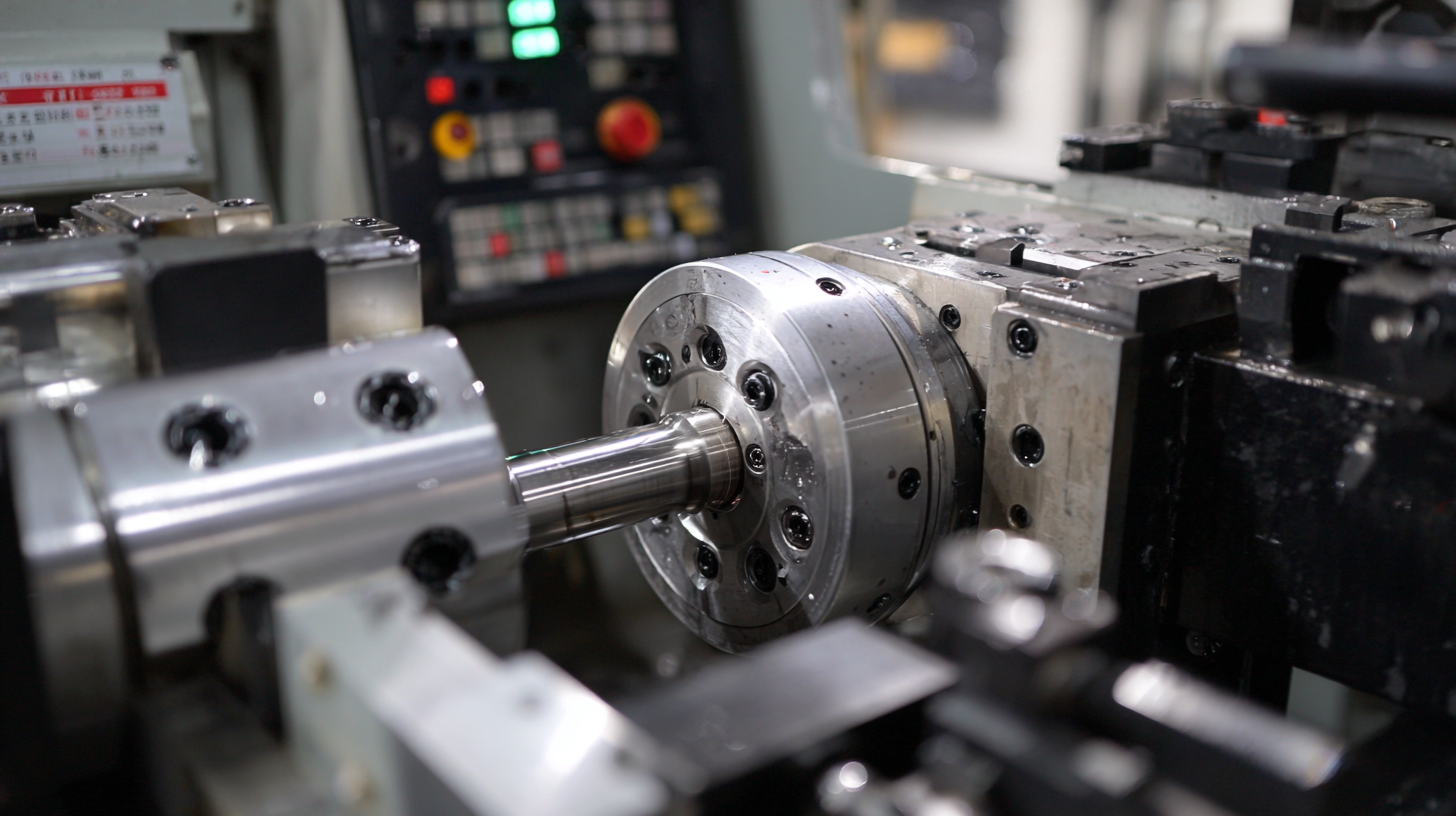

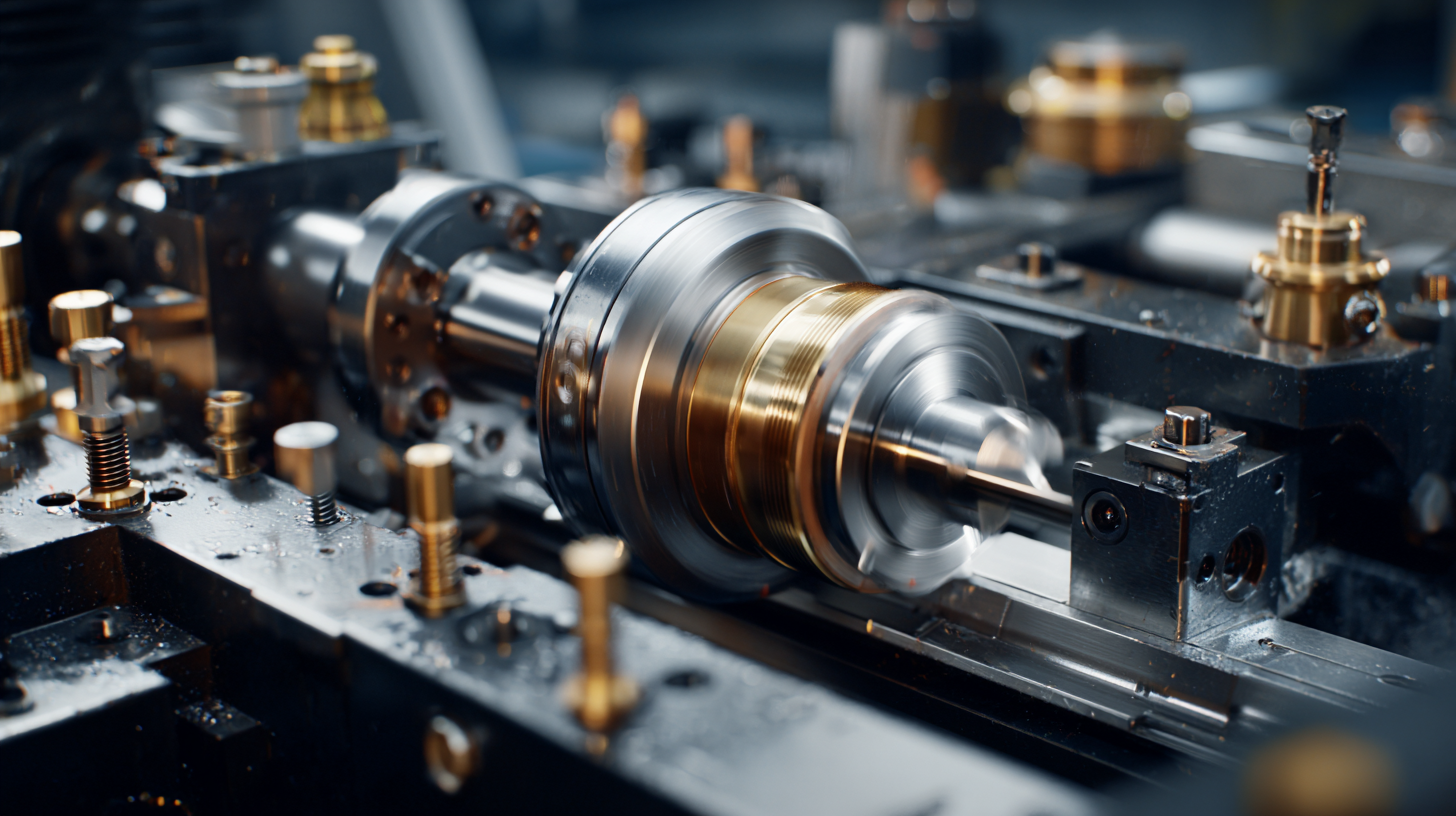

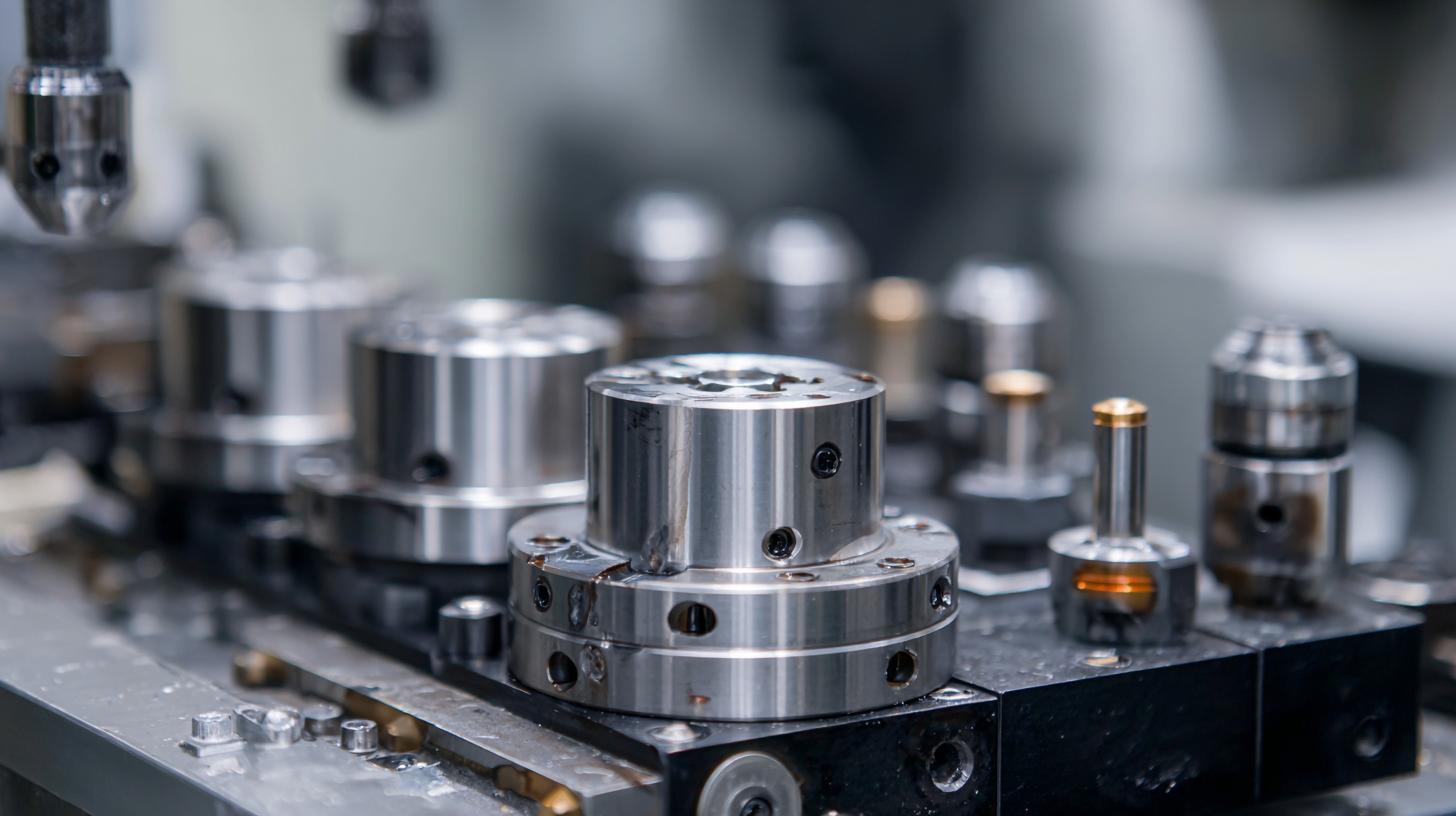

Thread rolling machines, known for their ability to produce high-strength threaded components efficiently, are becoming indispensable in industries ranging from automotive to aerospace. As manufacturers gear up to embrace advanced automation and smart manufacturing practices, understanding the diverse types of thread rolling machines and their specific applications will be crucial.

This blog will explore the defining characteristics and suitable applications of various thread rolling machine alternatives, positioning businesses to thrive in the evolving global landscape.

Future Innovations in Thread Rolling Technology for Enhanced Efficiency

The thread rolling industry is on the cusp of significant transformation as we look towards 2025. Innovations in thread rolling technology promise to enhance efficiency and productivity, addressing the growing demands of a competitive global market. With the integration of advanced robotics, manufacturers can expect to see automated systems performing complex thread rolling tasks with precision and speed, reducing the chances of human error and increasing output rates. The adoption of artificial intelligence in machine operations will enable predictive maintenance, ensuring that equipment remains in optimal condition and minimizing downtime.

Moreover, the future will see an emphasis on sustainable manufacturing practices. Thread rolling machines are likely to incorporate energy-efficient systems that reduce power consumption. These machines will be designed with eco-friendly materials, adhering to global environmental standards. Not only will these advancements benefit manufacturers economically by lowering operational costs, but they will also appeal to environmentally conscious consumers who prioritize sustainability. As we embrace these technological innovations, the thread rolling industry is set to redefine its role in modern manufacturing, paving the way for enhanced competitiveness and efficiency in the years to come.

Embracing the Future of Manufacturing: 2025 Trends for Best Thread Rolling Machines

Sustainable Manufacturing Practices in Thread Rolling Machine Production

In the evolving landscape of manufacturing, sustainable practices are becoming increasingly vital, especially in the production of thread rolling machines. As manufacturers strive to reduce their environmental impact, a focus on energy efficiency, waste reduction, and responsible sourcing is emerging. By integrating renewable energy sources and optimizing production processes, companies can minimize their carbon footprints while enhancing productivity.

Furthermore, the adoption of eco-friendly materials is gaining traction within the industry. Manufacturers are exploring biodegradable and recyclable options for machine components, thereby reducing their reliance on nonrenewable resources. This shift not only speaks to the growing consumer demand for sustainability but also positions companies favorably in a global market that increasingly prioritizes eco-conscious practices.

Embracing these sustainable manufacturing practices is not just a trend; it's a necessity for those aiming to thrive in the competitive future of the thread rolling machine industry.

Automation and AI: Transforming the Thread Rolling Process by 2025

The landscape of manufacturing is undergoing a seismic shift propelled by automation and artificial intelligence (AI), particularly in the realm of thread rolling. By 2025, these technological advancements are set to redefine processes, improve efficiency, and enhance product quality within the industry. Studies indicate that companies leveraging AI can expect productivity increases by up to 40% as streamlined workflows and real-time data analytics replace traditional methods. AI's ability to conduct inline inspections through optical technology will further ensure that quality control is integrated into every phase of production, fostering a zero-defect manufacturing environment.

The convergence of AI with automation not only boosts operational performance but also highlights a shift towards Industry 5.0, where the collaboration between machines and human workers is essential. As per industry forecasts, the demand for thread rolling machines equipped with AI capabilities is anticipated to grow significantly, reflecting a broader trend towards adaptive manufacturing technologies. With businesses reporting improved outcomes through AI integration, we can predict a future where intelligent systems enhance human skills, leading to smarter production lines and more innovative approaches in manufacturing processes by 2025.

Key Performance Indicators for Selecting the Best Thread Rolling Machines

When selecting the best thread rolling machines in a rapidly evolving manufacturing landscape, understanding key performance indicators (KPIs) is crucial. These indicators serve as benchmarks to evaluate the efficiency, reliability, and productivity of thread rolling machines. One of the primary KPIs is the machine’s cycle time, which reflects how quickly it can produce a finished product. Shorter cycle times not only increase output but also reduce operational costs, making machines that optimize speed crucial for competitive positioning.

Another vital KPI is tool life, which gauges the durability and longevity of the thread rolling dies. Machines that minimize wear and tear on tools contribute to lower maintenance costs and consistent product quality. Additionally, the accuracy of the thread profile is essential, as precise threading ensures compatibility with various applications and minimizes rework. Manufacturers should also consider the machine’s versatility, particularly how well it can handle different materials and thread geometries. By focusing on these key performance indicators, businesses can make informed decisions to embrace the future of manufacturing effectively.

Embracing the Future of Manufacturing - Key Performance Indicators for Selecting the Best Thread Rolling Machines

| Model | Max Capacity (tons) | Cycle Time (seconds) | Power Consumption (kW) | Precision (mm) | Cost (USD) |

|---|---|---|---|---|---|

| Model A | 10 | 5 | 15 | 0.02 | 20000 |

| Model B | 12 | 4 | 18 | 0.015 | 25000 |

| Model C | 8 | 6 | 10 | 0.03 | 18000 |

| Model D | 15 | 3 | 20 | 0.01 | 30000 |

Navigating Global Market Trends: Adapting to Regional Demands in Manufacturing

As we navigate the evolving landscape of manufacturing, the integration of the Internet of Things (IoT) is set to redefine industry standards, with the global IoT manufacturing market valued at $97.03 billion in 2023. This market is projected to grow substantially, reaching $116.52 billion by 2024 and an astounding $673.95 billion by 2032. Such growth underscores the need for manufacturers to adapt to these technological advancements while addressing regional demand variations that can influence production approaches.

In the niche of manufacturing equipment, trends reveal a notable shift towards advanced technologies, emphasizing the importance of innovation. For example, the global LED display market is expected to expand from $8.95 billion in 2024 to $13.77 billion by 2033, with a compound annual growth rate of 4.9%. This growth signals a rising interest in efficient and high-quality display solutions, compelling manufacturers to tailor their offerings to meet these emerging market needs. In the face of a challenging labor market forecasted by the International Labour Organization, driven by economic slowdowns, manufacturing entities must adopt strategic measures to harness opportunities presented by technological evolution and shifting consumer preferences.