- About

- Welders

- - Automation

- - Bench Welders

- - Capacitor Discharge Welders

- - Custom Resistance Welders

- - Diffusion Welding

- - Metal Door and Frame Welders

- - MFDC Welding

- - Multi-Gun Welders

- - Press Type Welders

- - Rocker Arm Spot Welders

- - Seam Welders

- - Spot Welding Guns

- - Turntable Welders

- - Used Welders and Equipment

- - XY Welders

- Blog

- TECNA

- Fastener Welding

- Supplies

- Services

- Resources

- Contact

Maximizing Efficiency: The Future of Water Chiller Systems in Sustainable Industrial Practices

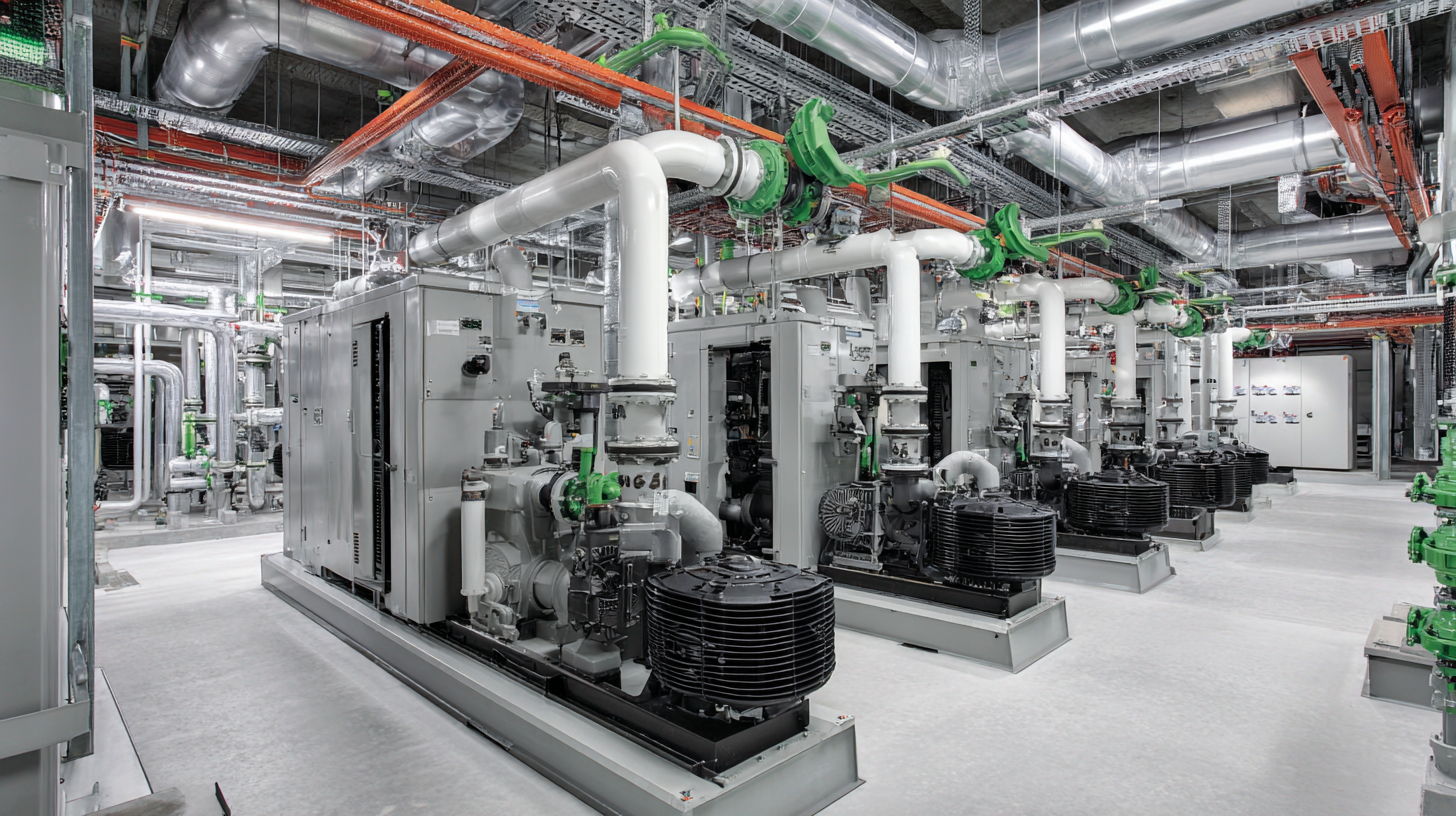

The increasing demands for energy efficiency and sustainability in industrial practices have propelled the evolution of water chiller systems. According to a report by the U.S. Department of Energy, HVAC systems, including chillers, represent nearly 40% of the total energy consumption in commercial buildings, highlighting the significant impact that optimization can have on overall energy use. As industries strive to reduce their carbon footprint, adopting advanced water chiller systems that leverage intelligent controls and eco-friendly refrigerants becomes essential. Furthermore, the global market for industrial chillers is expected to reach $12 billion by 2025, driven by the growing emphasis on efficient energy management and the use of sustainable technologies. In this context, understanding how to maximize the efficiency of water chiller systems not only aligns with regulatory compliance but also fosters competitive advantages in a resource-constrained environment.

Understanding the Role of Water Chiller Systems in Sustainable Industrial Practices

Water chiller systems play a crucial role in sustainable industrial practices by enhancing energy efficiency and reducing environmental impact. These systems are designed to remove heat from a liquid via a vapor-compression or absorption refrigeration cycle, making them essential for cooling processes in manufacturing, HVAC, and refrigeration applications. By optimizing the cooling process, industries can minimize energy consumption, thereby decreasing greenhouse gas emissions and overall operational costs.

**Tips:** To further improve the efficiency of water chiller systems, consider implementing regular maintenance schedules to ensure optimal performance. Upgrading to variable speed drives can also significantly reduce energy usage, as these drives allow the chiller to adjust its output according to demand, leading to more efficient energy utilization.

In addition, the integration of advanced technologies such as smart sensors and IoT (Internet of Things) devices can provide real-time monitoring and predictive analytics. These technologies enable industries to optimize their cooling loads and detect issues before they become critical. By adopting these innovations, businesses can not only achieve sustainability goals but also enhance reliability and reduce downtime in their operations.

Key Technologies Driving Efficiency in Modern Water Chiller Systems

Modern water chiller systems are at the forefront of improving energy efficiency in industrial practices. With the increasing demand for sustainable operations, key technologies are emerging to optimize chiller performance. One such technology is variable speed drives (VSDs), which allow chillers to adjust their operation based on actual cooling demand, significantly reducing energy consumption during off-peak hours.

Tips: To maximize the benefits of VSDs, industries should schedule regular maintenance checks to ensure the system is running smoothly. Monitoring software can also provide real-time insights into energy usage, helping identify opportunities for further optimization.

Another innovative development is the integration of smart controls and IoT technologies. These systems enable remote monitoring and automated adjustments, enhancing energy efficiency and operational reliability. By leveraging data analytics, facilities can predict maintenance needs and avoid costly downtimes.

Tips: Implementing smart control systems can require an upfront investment, but the long-term energy savings can offset costs. Additionally, training staff on new technologies ensures they can effectively manage and maximize the efficiency of modern water chiller systems.

Strategies for Optimizing Water Chiller Performance in Industrial Settings

In the context of industrial settings, optimizing water chiller performance is paramount to achieving sustainability goals and improving overall efficiency. According to a report by the U.S. Department of Energy, industrial cooling accounts for nearly 75% of a facility's energy consumption. By implementing strategies such as variable frequency drives (VFDs) and advanced control systems, facilities can reduce energy usage by up to 30%. Additionally, utilizing free cooling methods, when outdoor temperatures permit, can significantly cut operational costs associated with chiller systems.

Another critical strategy involves regularly scheduled maintenance and the use of predictive analytics to monitor system performance. The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) suggests that proper maintenance can enhance system efficiency by at least 15%. Moreover, integrating IoT technology allows for real-time monitoring, enabling quick adjustments and reducing downtimes. With these approaches, industries can not only improve the efficiency of their water chillers but also contribute positively to their environmental footprint, making strides towards sustainable industrial practices.

Integrating Renewable Energy Solutions with Water Chiller Systems

The integration of renewable energy solutions with water chiller systems marks a significant step towards sustainable industrial practices. As industries strive to minimize their carbon footprint, the combination of solar, wind, or geothermal energy with traditional chiller systems offers a pioneering approach. By harnessing these renewable sources, facilities can operate chillers more efficiently, thus reducing dependency on fossil fuels and lowering overall energy costs.

Moreover, the use of smart technology to optimize energy consumption can further enhance the performance of water chillers powered by renewable resources. Advanced monitoring systems allow for real-time adjustments, ensuring that cooling demands are met while simultaneously maximizing energy savings.

This transition not only contributes to environmental sustainability but also provides industries with a competitive edge in an increasingly eco-conscious market. Ultimately, the synergy between renewable energy and water chillers not only supports operational efficiency but also aligns with global sustainability goals.

Measuring and Analyzing the Impact of Efficient Water Chillings on Sustainability Goals

The growing emphasis on sustainability has led industries to explore more efficient water chiller systems. Efficient cooling systems are essential not only in enhancing operational productivity but also in minimizing environmental impact. According to a report from the U.S. Department of Energy, conventional chiller systems can consume up to 30% of a facility's total energy use. By upgrading to high-efficiency chillers, businesses can reduce energy consumption by 20-50%, significantly lowering their carbon footprint.

Moreover, the implementation of advanced water chilling technologies, such as magnetic bearing chillers and variable speed drives, has shown promising results in supporting sustainability goals. Research from the International Institute for Refrigeration indicates that implementing these systems can lead to a reduction in greenhouse gas emissions by more than 30% over their lifecycle. As more companies adopt these technologies, the measurable impact on sustainability will become increasingly apparent, ultimately fostering a more responsible and resource-efficient industrial landscape.

Related Posts

-

The Science Behind Portable Water Chillers and Their Impact on Sustainable Cooling Solutions

-

Understanding the Benefits of Using a Portable Water Chiller for Your Outdoor Adventures

-

How to Optimize Your Industrial Processes with a Recirculating Water Chiller

-

Exploring the Impact of Water Chiller Systems at the 138th Canton Fair in 2025

-

Exploring the Future of Industrial Chillers at the 138th Canton Fair 2025: Trends and Innovations

-

Exploring the Future of Weld Nuts at the 138th Canton Fair 2025: Trends and Opportunities in Manufacturing