- About

- Welders

- - Automation

- - Bench Welders

- - Capacitor Discharge Welders

- - Custom Resistance Welders

- - Diffusion Welding

- - Metal Door and Frame Welders

- - MFDC Welding

- - Multi-Gun Welders

- - Press Type Welders

- - Rocker Arm Spot Welders

- - Seam Welders

- - Spot Welding Guns

- - Turntable Welders

- - Used Welders and Equipment

- - XY Welders

- Blog

- TECNA

- Fastener Welding

- Supplies

- Services

- Resources

- Contact

What is a Switching Power Supply and How Does It Work?

In the realm of electronics, the "Switching Power Supply" (SPS) stands out as a crucial component. Expert John Doe, a well-respected figure in power electronics, once noted, "Switching Power Supplies revolutionize efficiency." His insight highlights the significance of SPS in modern devices.

Switching Power Supplies use a different approach than traditional linear power supplies. They convert electrical energy more efficiently, which reduces heat and saves space. This efficiency allows them to power everything from smartphones to industrial machinery. As technology advances, the need for compact and efficient power solutions grows.

However, designing a robust Switching Power Supply comes with its own set of challenges. Engineers must balance efficiency with electromagnetic interference and component reliability. It's a field that requires continuous reflection and adaptation. The quest for optimal designs is ongoing, and each failure is a chance to learn and improve.

Understanding the Basics of Switching Power Supply Technology

Switching power supply technology is essential in modern electronics. It converts one voltage level to another efficiently. This process involves turning the input voltage on and off at a high frequency, using electronic switches, typically transistors. By doing so, it reduces energy loss compared to traditional linear supplies.

An interesting aspect is the transformer’s role in this system. It can adjust voltage levels, but it also adds complexity. The filter circuits smooth the output voltage, ensuring stable power. However, this can lead to noise issues in sensitive devices. Additionally, the switching frequency can affect efficiency, but higher frequencies can help reduce size.

While switching power supplies are common, they are not without challenges. Thermal management is crucial. Without proper cooling, performance can degrade. Engineers must balance size, cost, and efficiency. Ignoring these factors can lead to unexpected failures, even in well-designed systems. Thus, continuous improvement and reflection are necessary in this rapidly evolving field.

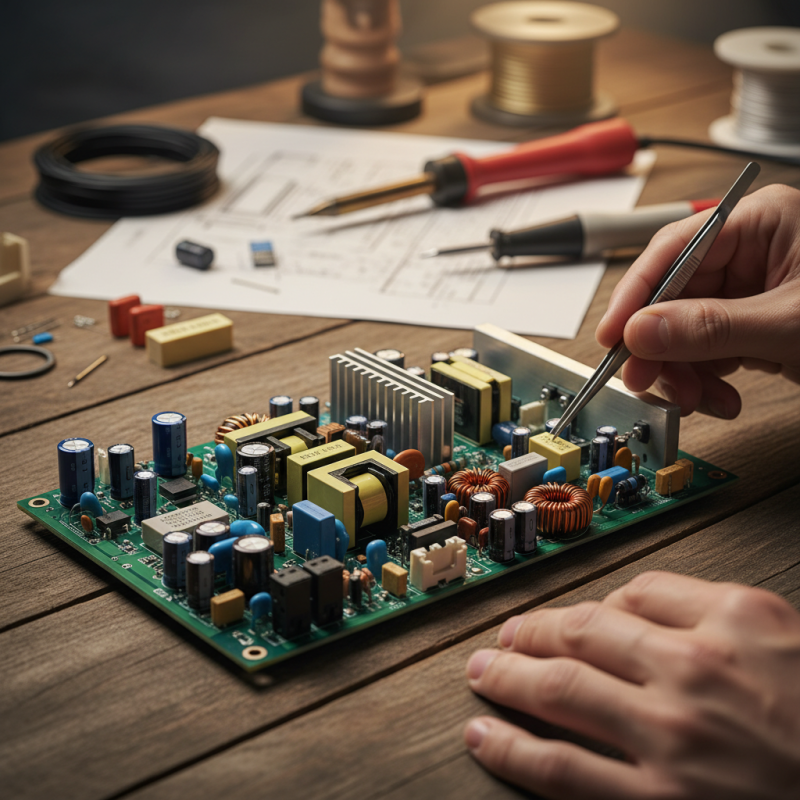

Key Components of Switching Power Supplies: An Overview

Switching power supplies are vital in modern electronics. They efficiently convert electrical power from one voltage to another. Key components define their functionality. Among these components, the switching transistor is crucial. It regulates and controls the energy flow, impacting the overall efficiency of the device.

Another important element is the transformer. It steps the voltage up or down based on design requirements. This transformation is necessary for adapting to various appliance needs. According to industry reports, transformers in switching power supplies can achieve up to 95% efficiency. This is remarkable when compared to linear power supplies. However, not every design achieves this ideal efficiency.

Filters also play a significant role. They help reduce electromagnetic interference. Unfortunately, poor filter design can lead to increased noise levels. This can disrupt the overall performance of electronic devices. Designers must pay careful attention to these components. Balancing cost and performance is always a challenge. Each component must meet specific standards to ensure reliability.

How Switching Power Supplies Achieve High Efficiency Ratings

Switching power supplies are known for their remarkable efficiency. They achieve this by using high-frequency switching to control power flow. Instead of generating waste heat, they convert electricity with minimal losses. This increases the overall efficiency, making them ideal for various applications.

One key factor in achieving high efficiency is the use of inductors and capacitors. These components help smooth out voltage fluctuations. They also store energy briefly, reducing energy waste during conversion. However, their selection can be tricky. Choosing the wrong values can lead to inefficiencies.

**Tip:** Always consider component ratings carefully. A mismatch might affect the entire circuit's performance.

Another aspect is pulse-width modulation (PWM). This technique controls the amount of power supplied. By quickly turning the power on and off, PWM minimizes energy loss. Yet, it requires precise timing. A slight deviation can lead to lower efficiency.

**Tip:** Experiment with different PWM frequencies to see what works best. It might require some trial and error.

In blending these methods, engineers can design power supplies that exceed 90% efficiency. But achieving high efficiency often comes with trade-offs. Balancing performance, size, and cost is essential. Each choice impacts the final outcome, making it a reflective process.

Efficiency Ratings of Different Power Supply Types

The Role of Pulse Width Modulation in Switching Power Supplies

Pulse Width Modulation (PWM) is crucial in the operation of switching power supplies. This technique controls the voltage and current delivered to the load. At first glance, PWM may seem complex, but its essence lies in varying the width of pulses in a regular waveform. It's like flickering a light switch on and off quickly. The average power reaches the load through these adjustments.

By changing the pulse width, PWM alters the effective voltage sent to a device. For instance, when the pulse is wide, more power is delivered. Conversely, a narrow pulse results in less power. This dynamic control allows devices to maximize efficiency while minimizing heat loss. However, it’s not always perfect. Some devices may respond poorly to rapid changes. The production of electromagnetic interference can also lead to unforeseen issues in sensitive equipment.

In practice, implementing PWM requires careful consideration. It demands attention to detail. The frequency of the switching can impact overall performance. A too-high frequency may lead to increased switching losses. Engineers must find a balance that suits their specific application. Understanding these nuances is essential in refining the design of efficient power supplies.

Common Applications and Benefits of Switching Power Supplies in Industries

Switching power supplies are widely used in various industries. They convert electrical power efficiently, offering high performance. These devices are crucial in powering everything from computers to industrial machines. With the ability to adapt to different voltage requirements, they provide significant flexibility.

In automotive applications, for example, switching power supplies aid in regulating power within vehicles. They ensure the electronic systems function reliably. In consumer electronics, smaller profile designs are beneficial. More compact units take up less space without compromising performance.

Tips: Always check the specifications before making a purchase. Know your power needs, as it directly affects compatibility. Additionally, consider ventilation when integrating these supplies to prevent overheating.

Industries benefit from the energy savings switching power supplies provide. They reduce waste and lower energy costs. However, there's a learning curve in their operation. Engineers must understand complex circuitry to implement them effectively. Mistakes in design can lead to inefficiencies or failures.

Tips: Test configurations before mass production. It ensures reliability and longevity. Collaborate with engineers experienced in these technologies. Their insights can help avoid common pitfalls.

What is a Switching Power Supply and How Does It Work?

| Parameter | Value |

|---|---|

| Input Voltage Range | 100-240V AC |

| Output Voltage | 5V, 12V, 24V DC |

| Efficiency | 80-95% |

| Common Applications | Consumer Electronics, Industrial Equipment, LED Lighting |

| Size | Compact design for space-saving |

| Weight | Lightweight compared to linear power supplies |

| Regulation | Stable output under varying load conditions |

| Protection Features | Short-circuit, Over-voltage, Thermal protection |